Average Power Saving of More Than 40% By Using PanGood’s Fans

Release Time:2024.06.07

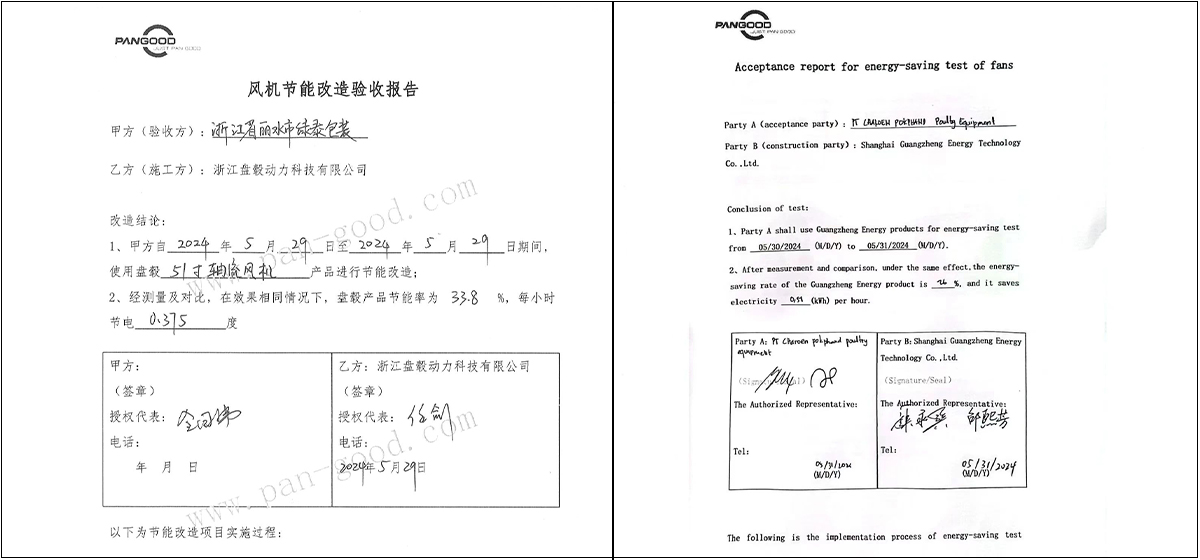

As the summer heats up, the ventilation and cooling needs of factories and workshops are becoming more and more urgent. Verification of actual working conditions in many places shows that, under the same wind speed and air volume, the average power saving rate of the PanGood’s fans driven by the "double power" motor are more than 40%.

On 5th June, the factory engineers of Ningbo Changhua Changsheng Auto Parts Co.,Ltd. and the technical engineers of PanGood jointly carried out the determination of energy-saving effect of PanGood 51-inch axial fan. The results indicate that in the case of the same ventilating and cooling effect, PanGood’s fans could realize power consumption by 0.493kWh per hour, and the energy-saving rate of 50%.

Prior to this, PanGood’s fans have already passed the energy-saving acceptance of various customers in Jiangmen, Guangdong Province, Lishui, Zhejiang Province, as well as in Indonesia. Everywhere, the excellent energy-saving performance of the fan has won high recognition and praise from end-users.

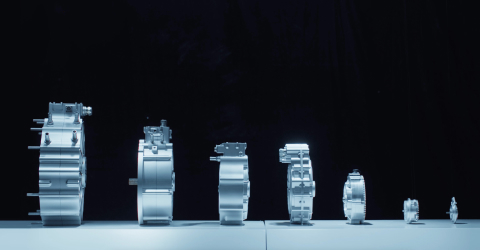

Compared with other fans on the market, PanGood’s fans adopt a number of innovative technologies such as the "X-POWER" axial flux motor, frequency control, swept fan blade, etc., which makes it the "three good standard-bearer" in the fan field and help customers save money and effort.

Good Fan ——30% power saving under the same air volume

Innovative axial flux motor technology, superior energy consumption standards, more than 90% of the working conditions motor can operate efficiently;

The motor directly drives the fan blade to rotate without belt drive, reducing energy consumption while lowering the cost of replacement of wear parts;

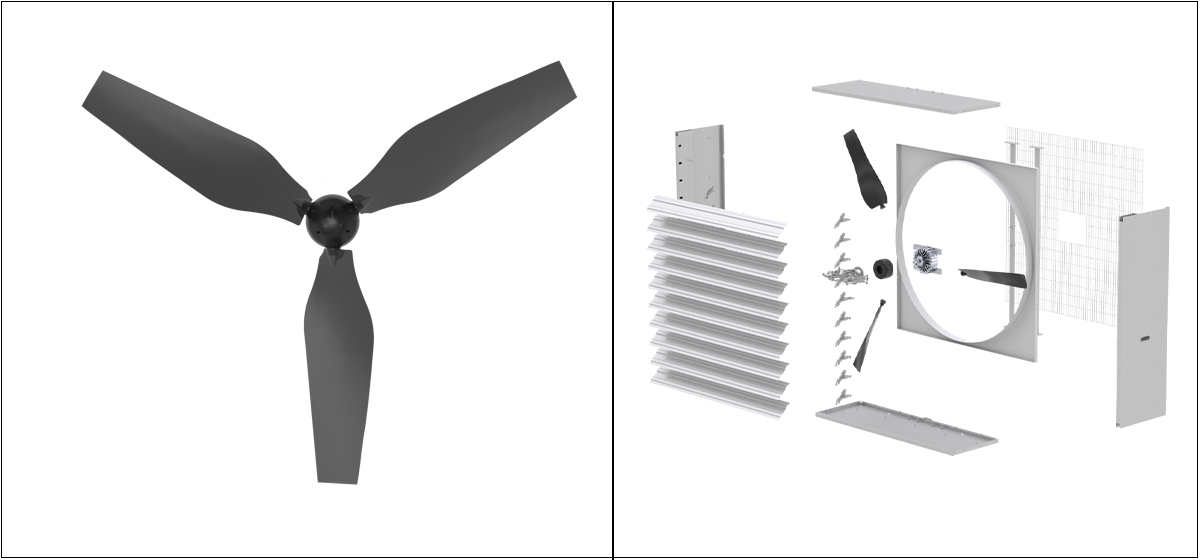

CFD simulation design of swept fan technology, air output efficiency is further improved and less power consumption.

Mature and reliable industrial inverter controllers can adjust the working frequency according to the environmental requirements to avoid ineffective consumption.

Outlet louvre design, the use of centrifugal components to open, reduce outlet resistance, while increasing the durability of the equipment.

Good Effect——Simple structure, easy to install and management

Innovative integrated design, no drive belt, fewer parts and simpler structure.

Motor weight is reduced by 55% and axial length by 60%, making installation and maintenance easier;

Only 3 fan blades are needed to achieve the same ventilation and cooling effect, further simplifying the structural components.

It can be equipped with intelligent sensors to realize digital management, integrated control, and early warning of faults, making management more worry-free.

Good Performance——Leading technology, good reliability, worry-free after-sales

The vehicel-grade verification standard and motor test standard are three times higher than the national standard, and the product quality is leading in all aspects;

All parts are made of high-quality materials, with good corrosion resistance and durability, easy to clean and maintain;

The motor is guaranteed for 2 years, no worries;

Built-in multiple safety protection functions ensure that the equipment can operate safely and stably in various environments.

Faced with the challenge of high temperatures in midsummer, PanGood’s axial flow fans have become the best choice for factory ventilation due to their excellent ventilation performance and average power saving of more than 40%. Its characteristics and advantages of saving money, worry and labor enable it to not only significantly improve the production environment, but also bring real economic benefits to the enterprise.

Looking into the future, PanGood will work closely with customers in more fields to innovate and jointly promote the technological revolution of the electric drive industry!