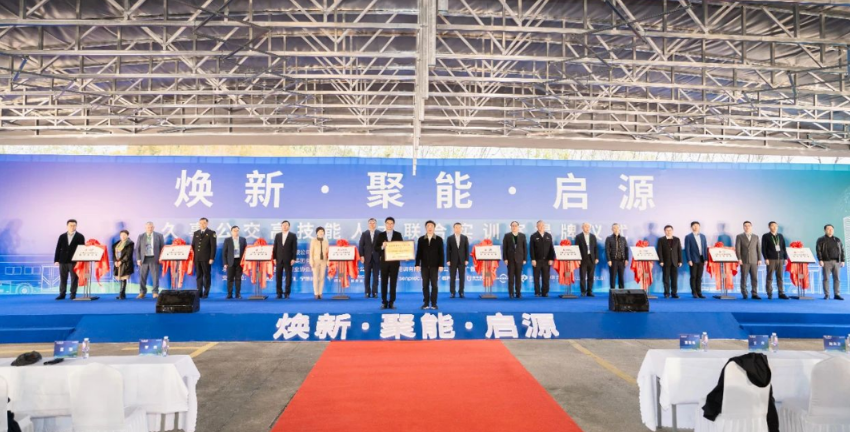

Cultivate High-skilled Talents and Promote Integration and Innovation | Shanghai Jiushi Public Transport Joint Training Room Unveiled

Release Time:2024.12.07

After nearly a year of preparation and construction, the Jiushi Bus High-skilled Talent Joint Training Room was unveiled in Shanghai on December 5. This training room is the first in China to bring together resources and technical strength from nine leading companies in the industry, including SUNWIN Bus, CATL, and PanGood, to provide a practical solution for the training of high-skilled talents in the industry.

One-stop full-skill training to accelerate the filling of the gap in high-skilled talents

In recent years, our country's urban public transportation sector has been transforming towards green, digital and intelligent. The number of new energy buses nationwide has reached 554,000, accounting for 81.2%. "New energy vehicles account for more than 90% of the city of Shanghai, but there is a large gap in the supply of related high-skilled talents." Xia Tian, general manager of Jiushi Public Transport Bus Training Center, said that there are nearly 2,500 automobile repairmen in Shanghai's public transportation industry, but there is a large gap in people with senior technician certificates, especially now that the new energy bus industry chain involves vehicle manufacturing, battery production, motor research and development, charging facility construction and other links, and the technology updates and iterations of these links are particularly fast. "If we can't keep up with the cutting-edge technology of the industry, then the high-skilled talents we train will definitely be out of touch with the actual needs of the industry."

Based on this, Jiushi Bus has joined hands with leading companies in the industry chain such as SUNWIN Bus, CATL, and PanGood to create a domestic industry-leading new energy training base, which is open to the whole society. The training projects involve various fields such as technical diagnosis of the whole vehicle, batteries, on-board air conditioning, drive motors, braking systems, charging equipment, etc. "Each field has its own training room, which provides detailed introductions to specific products and operating procedures, allowing participants to learn new technologies and principles of the entire industry chain in a 'one-stop' manner, and integrate them through practical operations. It can not only serve as a platform for production companies to demonstrate their own strength, but also solve the problems encountered by the industry in the training of high-skilled talents and practical applications," said General Manager Xia.

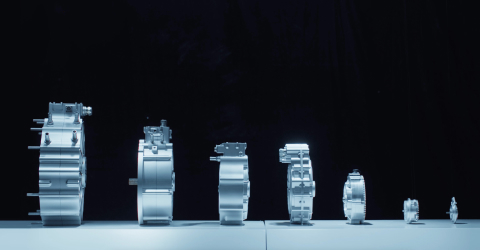

For example, in the whole vehicle training room of SUNWIN Bus, a set of industry-leading maintenance technology test benches are placed to simulate the high-voltage, low-voltage, gas circuit and other control systems of the whole vehicle, and provide training and teaching fault simulation functions; the battery training room of CATL displays various specifications of power batteries used in commercial vehicle electric boxes, as well as bus power battery intelligent disassembly and assembly training tables, bus high-voltage connector plug-in tables, power battery BMS diagnostic tables and other equipment to teach power battery maintenance operations; the motor and electric drive solution training room jointly built by PanGood and Jiushi Bus not only gives a detailed introduction to the "Metro Bus" distributed hub drive system and disassembly and assembly procedures, but also specially sets up axial flux drive motors and physical samples of "Metro Bus", so that trainees can quickly understand the products and get started quickly.

Li Ying, Second-level Inspector and Director of the Vocational Capacity Building Department of the Shanghai Municipal Human Resources and Social Security Bureau, believes that "the Jiushi Bus High-skilled Talent Joint Training Room has brought together leading domestic and foreign new energy vehicle industry companies. Everyone collaborates across industries, brings out the latest technologies and equipment on the same platform for open sharing, and actively explores the path of cultivating high-skilled talents for new energy buses, including public transportation. Such innovative practices are worth exploring."

New technologies lead the market trend, and more than 7,000 "Metro Bus" have been put into use

Shanghai is one of the first cities in the country to apply the "Metro Bus" bus model. Since 2020, Shanghai's public transportation industry has put into use a total of about 700 "Metro Bus" buses.

In mid-June 2024, the Shanghai Transportation Industry Association organized a special seminar on "High-tech and New Technology Empowering the High-quality Development of Shanghai's Public Transport Vehicles" to analyze and summarize the actual application and application effects of the "Metro Bus" distributed wheel hub drive technology buses. The meeting believes that after four years of actual operation verification of about 30 million kilometers, the distributed wheel hub drive technology of the "Metro Bus" "breaks the structure and framework of traditional buses. Its spacious carriages and flat floors are called "public transport subway cars" by passengers, representing the development direction of new buses and theoretically forming a new model of quality productivity."

"The transmission structure of distributed drive technology is simpler and the layout is flexible. The space utilization rate in the car is high and the transmission system is efficient. The motor is miniaturized and distributed, independently controlled, and has strong fault tolerance. Through the precise control of the torque and speed of the wheel-side motor, the vehicle driving, braking, energy feedback, electronic differential and other functions can be realized. This is an inevitable development trend of the future drive system." At the "Trend Forum on the Promotion and Application of New Energy Skills for Buses" held on the afternoon of December 5, Li Puyu, director of PanGood’s Solutions Department, said.

1.Fully flat low floor, barrier-free access

The entrance and exit of the passenger door are basically level with the floor of the bus station, making it more convenient to get on and off the bus;

The interior of the carriage is connected from front to back, with 0 steps, 0 steps, and a flat floor, allowing barrier-free passage;

The width of the rear aisle has been increased by 115mm, allowing wheelchairs, strollers, etc. to pass through easily.

2.Large space expansion, small models replace large ones

The drive motor and tires are highly integrated, which fully expands the interior space of the car, making it more spacious and comfortable than vehicles of the same level;

Super flexible transport capacity, with seats available during off-peak hours and more passengers during peak hours;

The 8-meter metro bus has the capacity of a 10-meter ordinary bus, and the 10-meter metro bus has the same passenger capacity as a 12-meter ordinary bus;

Smaller vehicle models replace larger ones, with lower operating costs per unit of capacity;

The smaller turning radius makes it more suitable for new buses to travel through streets and alleys under three-dimensional transportation.

3.More stable and comfortable, safer and more efficient

The distributed drive system accurately distributes wheel power, running more smoothly and turning more steadily;

The passenger door is placed behind the rear wheels to avoid accidents caused by crushing, which is more friendly to the elderly.

There is no reverse passenger flow inside the carriage, and getting on and off the train is smoother;

The highly integrated design reduces weight by 700~800kg compared to traditional drive systems, with an overall weight reduction of approximately 1,800kg.

As a star product of "public transportation service for the elderly", PanGood's "Metro Bus" public transportation solution has achieved disruptive functional improvements such as a fully flat floor that runs through the front and back of the car, 0 steps, 0 steps, extra-wide aisles, and "small car model replacing large one". As a result, it has attracted the attention and popularity of more and more public transportation operating companies, and the market demand has expanded rapidly. As of now, nearly 8,000 buses equipped with the "Metro Bus" solution have been promoted and applied in China.

Develop "new quality productivity" and drive the integration and innovation of the industrial chain

The strong demand from the market has also injected new impetus into the technological innovation of major bus manufacturers in the front-end production and manufacturing. The "black technology" represented by " Metro Bus" has received more and more attention from the main manufacturers, and its "circle of friends" has continued to expand.

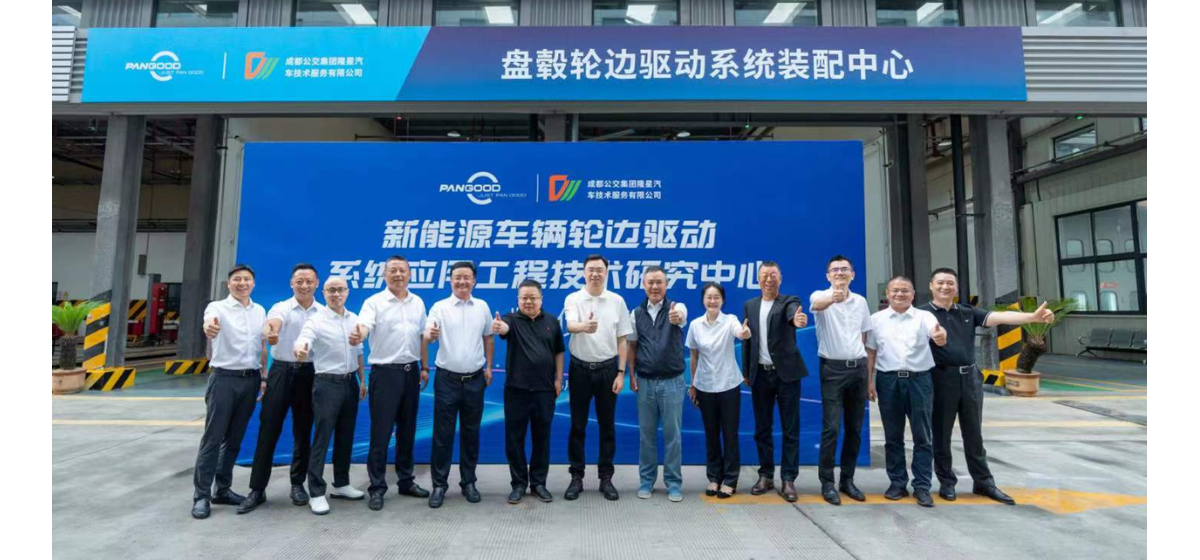

In June this year, the "New Energy Vehicle Wheel Drive System Application Engineering Technology Research Center" jointly built by PanGood and CRRC, CATL, Chengdu Public Transport and other partners was unveiled.The center brings together companies from all parties in the industry chain, including batteries, electric drives, vehicle design and development, and end users. Based on the actual operating environment and working conditions of new energy buses under the new situation, and based on the application of distributed drive technology, the center conducts in-depth research, positive development, and precise adaptation of the vehicle power system, continuously improving the happiness, satisfaction, and sense of gain of citizens' travel, and creating greater value upgrades for public transportation operations.

At the same time, the "wheel-side drive system assembly center" jointly built by PanGood and Chengdu Public Transport began to operate, realizing the localized assembly and localized operation of core components of urban public transport vehicles, and also created a new cooperation model of "new quality productivity" electric drive technology and terminal application scenarios;

At the end of October, PanGood's new energy commercial vehicle electric drive assembly manufacturing base was established in Datong, Shanxi, and a "joint operation center" was established with leading enterprises in the industry chain such as CATL and Shaanxi Automobile Group, which "packaged and promoted the technology research and development, production and manufacturing, assembly and other businesses of core components such as motors and electric drives together with vehicle manufacturers", "zero-distance cooperation" and integrated innovation.

Facing future development, PanGood will also work with partners in various industries and fields to "seek truth, innovate, and coexist", work together to promote the technological revolution in the electric drive industry.