Breaking the 30% Energy Saving Barrier! The Solid Path and Carbon Reduction Code for Energy-Consuming Equipment Retrofit in the Power Generation Industry

Release Time:2025.05.30

Against the backdrop of the accelerating global energy revolution and the "Dual Carbon" strategy, the power generation industry, as a crucial pillar of the energy supply system, is facing urgent challenges in energy conservation, consumption reduction, and the transition to green and low-carbon operations.

Since late May, the power generation industry has held numerous conferences, exploring pathways for high-quality development from various angles including policy interpretation, technological innovation, and industrial chain collaboration. Focusing on the scenarios and user needs within the power generation industry, PanGood was invited to attend multiple industry exchange events such as the "2025 China Waste-to-Energy Technology Innovation Summit Forum" and the "2025 National Technology Exchange Seminar on Energy Saving, Carbon Reduction, and Transformation/Upgrading for Small and Medium-Sized Thermal Power Units." At these events, PanGood presented its "Axial Flux Motor Solution for the Power Generation Industry."

Waste-to-energy plants and thermal power enterprises, as vital supporting forces in regional energy systems, have long played an irreplaceable role in ensuring industrial heating supply, serving public welfare, and providing power peak shaving. However, under the "Dual Carbon" goals, they now face multiple challenges including improving energy efficiency, reducing pollutant emissions, and undergoing transformation and upgrading.

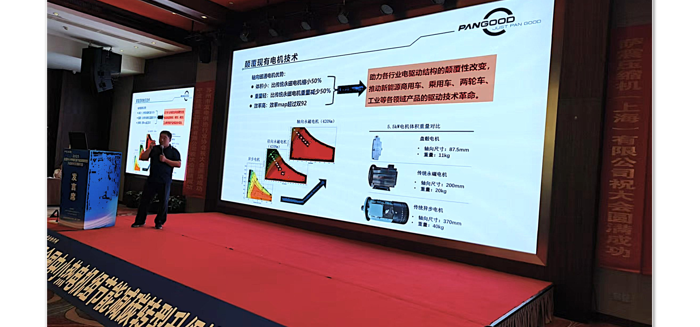

Power generation enterprises are also major "energy consumers," heavily utilizing electrically driven equipment in their daily production and operations. These devices commonly employ a drive system of "three-phase asynchronous motors + belt or multi-stage gearbox transmission." This setup suffers from low motor efficiency, high energy consumption, and requires regular maintenance and replacement of vulnerable parts like belts, leading to high operational costs for enterprises.

PanGood leverages its disruptive innovation and automotive-grade axial flux motor and electric drive technology. By combining on-site data and operating conditions for simulation and calculation, it enables precise matching and selection. This achieves systematic energy savings for various energy-consuming equipment across scenarios in the power generation industry, delivering an average energy saving rate of 10% to 30% under equivalent operational performance.

Taking Jinhua Ningneng Thermal Power as an example: in 2024, the company adopted PanGood's electric drive solutions to retrofit and upgrade multiple products, including desulfurization tower slurry pumps, demineralized water pumps, intake water pumps, and centrifugal fans. It then tracked and compared data on the actual application results.

Among these, a 110kW circulating slurry pump using the PanGood solution achieved a 27% reduction in hourly power consumption compared to the original motor under equivalent operating conditions. This translates to annual electricity savings of 101,000 kWh. At a unit price of 0.4983 yuan/kWh, this results in approximately 52,000 yuan in annual electricity cost savings.

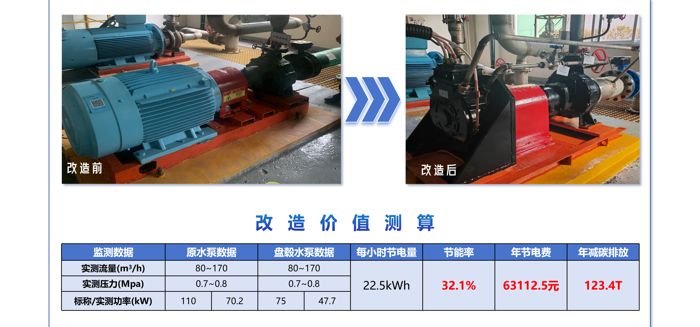

For a 110kW demineralized water pump operating at the same flow and pressure, the PanGood solution saved 22.5 kWh per hour compared to the original solution, achieving an energy saving rate exceeding 32.1%. This leads to annual electricity cost savings exceeding 63,000 yuan and reduces carbon emissions by 123.4 tons per year for a single unit.

A 30kW intake pump used in the external pump house, employing the PanGood solution, achieved an energy saving rate of 27.6%, resulting in annual electricity cost savings of approximately 13,900 yuan.

At the end of 2024, Ningneng Thermal Power's energy-consuming equipment energy-saving retrofit project won the "Third Prize for Green and Low-Carbon Technology Innovation in the 2024 Thermal Power Industry." Building on this multi-faceted win-win outcome encompassing energy conservation, emission reduction, economic benefits, and social value, Ningneng Thermal Power has further intensified its collaboration with PanGood. They are now innovatively applying and developing axial flux electric drive technology on more equipment, including centrifugal fans, feedwater pumps, and loaders.

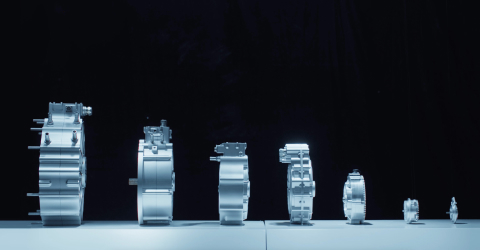

Looking at the overall distribution of energy-consuming equipment in power generation and thermal power enterprises, beyond common products like pumps and fans, PanGood's solution of "Axial Flux Motor + Planetary Gearbox" can also be applied to various other equipment, including belt conveyors, coolers, unloaders, slag skimmers, and slag removers. This provides an energy-saving upgrade path for replacing the existing "three-phase asynchronous motor + belt or multi-stage gearbox transmission" systems.

In more and broader application scenarios, products based on PanGood's axial flux motor and electric drive technology hold even greater potential for benefits.

For instance, in material and waste transportation, applying PanGood's electric drive solution for the "diesel-to-electric" conversion of a 5-ton loader can save 200,000 to 300,000 yuan compared to purchasing a new one. While achieving "zero emissions in one step," it reduces fuel costs by over 75% compared to diesel models and halves vehicle maintenance workload and costs. A single charge supports 5-6 hours of continuous operation with no power interruption under all working conditions. Its modular design enables short retrofit implementation cycles and rapid results. Every day of early adoption means early returns!

Based on technological innovation and targeting energy saving and carbon reduction, PanGood's highly efficient electric drive technology creates game-changing value improvements and upgrades for users. It provides practical and feasible solutions for power generation and thermal power enterprises in their energy-saving, carbon-reducing transformation and upgrading. PanGood looks forward to working with you to jointly create a green future for the thermal power industry!