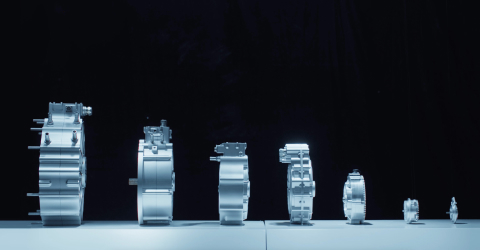

With the support of aviation "core technology", China's first carbon fiber composite BMT was born!

Release Time:2021.05.08

On April 26, 2021, Qingdao entered the "Shanghai Cooperation Organization (SCO)" time. The 2021 Shanghai Cooperation Organization International Investment and Trade Expo and the Shanghai Cooperation Organization Local Economic and Trade Cooperation Qingdao Forum with the theme of "sharing the opportunities of the Shanghai Cooperation Organization and seeking open development together" was held.

On April 26, 2021, Qingdao entered the "Shanghai Cooperation Organization (SCO)" time. The 2021 Shanghai Cooperation Organization International Investment and Trade Expo and the Shanghai Cooperation Organization Local Economic and Trade Cooperation Qingdao Forum with the theme of "sharing the opportunities of the Shanghai Cooperation Organization and seeking open development together" was held.

On this new platform of “The Belt and Road (B&R)” international cooperation, the first carbon fiber composite BMT, a new energy bus equipped with a brand-new “aviation core technology”, was unveiled, achieving a new breakthrough in bus manufacturing. Director of the Expert Advisory Committee of Shanghai Cooperation Demonstration Ren Zhaoai, Dean of Zhejiang Tsinghua Yangtze River Delta Military-civilian Collaborative Innovation Research Institute Rong Yichao and other expert leaders attended the launch ceremony.

New energy and light weight are necessary paths for the development of the automobile industry. In recent years, energy-saving, emission-reduction and lightweight requirements have brought earth-shaking changes to the automotive industry. Industrial structure, technical system and market demand undergoes changes in accordance. Lightweight technologies and applications have ushered in a window period.

When it comes to lightweight cars, carbon fiber materials bear the brunt. This form of technology, which was born in the 1960s and 1970s, seemed to be disruptive at the time. It can transform plastics into structural materials and change the performance of plastics to that of aluminum. The alloy is similar, but lighter in weight. Therefore, the emergence of carbon fiber has first been favored by national defense aerospace.

Domestic carbon fiber is limited by its high cost, which limits its commercial application in civilian passenger cars. Some domestic automobile covering parts and decoration parts use carbon fiber composite materials, and the load-bearing structure is still a metal structure. Nevertheless, the production cost of composite material structure is high and it is difficult to apply on a large scale.

The carbon fiber composite BMT released this time was jointly developed by Zhejiang Tsinghua Yangtze River Delta Innovation Research Institute and other units, breaking through the key technologies of carbon fiber composite modular carrying body design as well as low-cost, efficient manufacturing and assembly, and successfully realizing the industrialization of aviation composite technology.

The whole car adopts 100% domestic carbon fiber composite materials, and through four innovative technologies, the goal of lightweight, commercial and industrialization of carbon fiber bus bodies has been achieved, leading the development of the automotive lightweight industry, achieving automotive energy saving and emission reduction, and helping green and low-carbon developments.

Wang Honghai, deputy dean of Zhejiang Tsinghua Yangtze River Delta Military-Civil Collaborative Innovation Research Institute, said: “This product is our country’s first product in the field of carbon fiber composite materials that can truly achieve large-scale applications. It is our high-tech aerospace carbon fiber technology. The embodiment of low-cost applications in the civilian field."

It is understood that the carbon fiber composite BMT adopts a PanGood-powered wheel-side independent suspension drive system and a multi-material body that integrates aviation carbon fiber composite technology. The vehicle is lightweight and weighs 2600-3000kg, and the ride efficiency is increased by 50%. The number of standing areas has increased by 69%, and the power consumption and energy consumption have been greatly reduced, realizing economic and efficient operation. The car has a flat floor, a large aisle layout, and a rear wheel aisle of 800mm, achieving barrier-free and fast traffic. The PanGood power used by the BMT bring a more efficient, safe and comfortable mobile travel experience for passengers.

The carbon fiber composite BMI equipped with PanGood electric motor is expected to achieve mass production and delivery of "100 vehicles in a hundred years" within this year, presenting the party's centenary with its fruitful innovations!