Power saving rate 58.3%! PanGood’s industrial fan helps Taiya shares to upgrade energy saving!

Release Time:2023.04.17

Quanzhou, Fujian, known as the "Shoe Capital of China", has produced many world-renowned sportswear brands such as Anta, Xtep, 361 Degrees, and Guirenniao. As the "largest sole manufacturer in Quanzhou", Quanzhou Taiya Shoes Co., Ltd. (hereinafter referred to as "Taiya Shoes") is constantly looking for ways to save energy and reduce carbon emissions in the wave of industrial manufacturing 4.0. Now, they are close to the right answer.

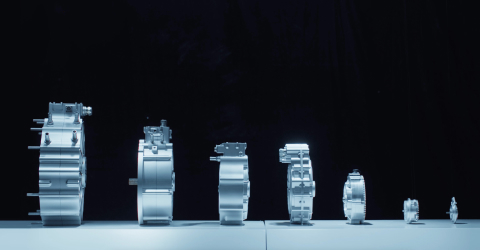

In the production workshop on the third floor of Taiya Shoes, two sets of AFM200-1.5K-1500 fans using PanGood’s axial flux motor were quietly put into operation. The difference from the previous one is that the two newly installed wind turbines are each equipped with independent electricity meters; and the adjacent comparison wind turbines are each equipped with an electricity meter. "We want to accurately calculate the actual application effect and power consumption of the lower PanGood’s wind turbine through power consumption statistics," said Wang Xiaoming, administrative manager of Taiya Group.

There are 32 fans in total in the production workshop on the third floor of Taiya Shoes. "The fan is the main equipment for exhaust and heat dissipation in the workshop. We have to turn on the fan for about 200 days a year to dissipate heat," said Wang Xiaoming. Because the production of soles requires a lot of gluing processes, the heat in the workshop is very high, and it is unrealistic to install air conditioners. So when the weather is hot, we can only rely on the fan to absorb the heat out of the window to maintain the comfort of the temperature inside the workshop. The air intake of the fan is our main consideration.

Based on the actual business application needs of customers, PanGood has optimized the design of the blade material and manufacturing process of this new type of fan, and at the same time adopted a more efficient, smaller and lighter axial flux motor to match it, making improvements and upgrades in many aspects. "From a physical point of view, the fan of PanGood has a large air intake volume. You can feel the strong wind 2 meters away from the fan. This effect is far better than another fan we launched at the same time. The difference in effect is very large."

The other difference comes from the statistics of power consumption. According to the electricity meter statistics of Taiya Shoes, in the same period of time, the total power consumption of PanGood’s fan was only 453 kWh, while the power consumption of the comparison fan was 1092 kWh, more than double the difference. "The result of this comparison is beyond our company's expectations," said Wang Xiaoming. According to this data, the power saving rate of PanGood’s fan reaches 58.3%, while the power saving rate of another PanGood’s fan installed during the same period also reaches 56%.

"The application of the PanGood’s fan has greatly helped our factory accelerate the green and low-carbon development," Wang Xiaoming said that old fans not only consume a lot of electricity and have poor ventilation effects, but are also prone to malfunctions, affecting workshop production. Currently, the fans in the production workshops on the first and second floors of the factory are on the verge of being replaced. " "The new PanGood’s fan with good air exchange effect and nearly 60% electricity saving will undoubtedly be our first choice."