Instead of 7190 kWh of electricity, only 2373 kWh is needed! Using PanGood’s axial flow fan can save 5000 kWh of electricity per year!

Release Time:2023.07.08

In July, the weather in Guangdong has become so hot that it seems "as if there is no end in sight". Walking through the 40℃ scorching sun and into the weaving workshop of Junxiong Textile Factory, you can only feel the coolness. After using 10 54-inch PanGood’s axial flow fans, this workshop of more than 1,000 square meters filled with looms maintains a comfortable constant temperature of about 25℃ throughout the year.

General Manager of Junxiong Textile Factory Huo Fuxiong

"The workshops in textile factories are different from general manufacturing workshops. They need to be both closed and ventilated," said Huo Fuxiong, general manager of Junxiong Textile Factory. The weaving workshop needs a relatively closed environment to ensure that the overall humidity is controlled within the appropriate range of 50%-70%. At the same time, ventilation and dust removal are required to keep the dust concentration in the workshop within a limited range, while maintaining a constant indoor temperature of 25℃-27℃. "If air conditioning is used, the doors and windows need to be closed, and the indoor air is always circulating. After a long time, the pollution index will definitely get higher and higher, and the power consumption is very large, which is 8-10 times that of the ventilation window machine." The use of air coolers can maintain the air quality in the workshop while achieving the temperature and humidity required by the weaving process with less energy consumption. "It is a more ideal cooling and ventilation product."

Junxiong Textile Factory has installed and applied 10 PanGood’s axial flow fans

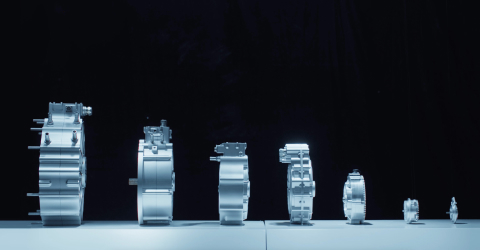

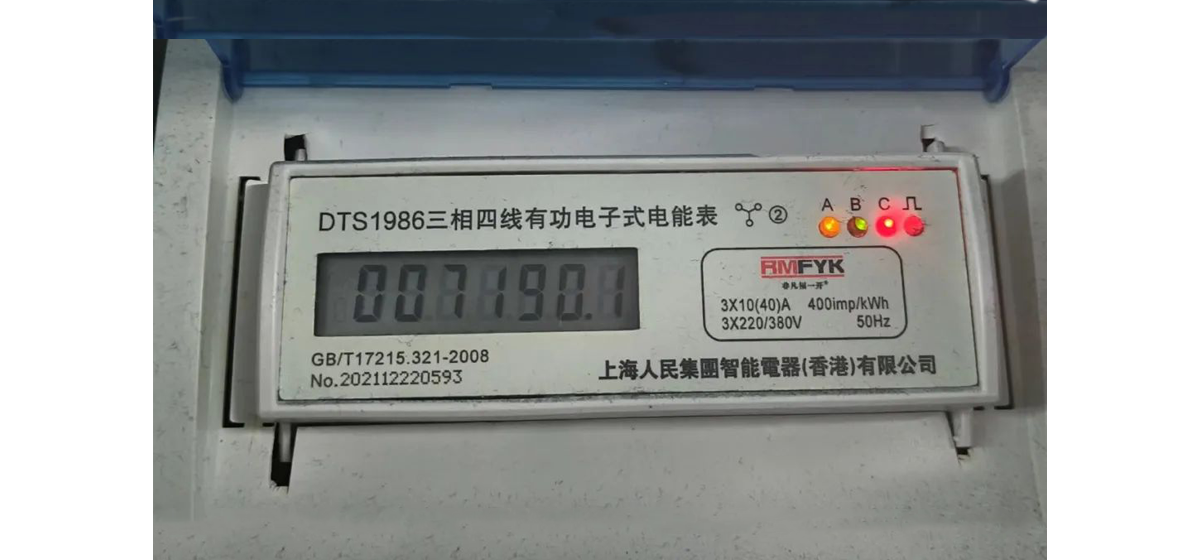

Compared with ordinary air coolers, axial flow fans that use PanGood’s axial flux motors not only have larger and more stable air volume and better ventilation effects, but also the motor efficiency can reach over 90% under working conditions above 90%. This also means that "this type of fan consumes less power and has lower operating costs." In order to test the actual use effect of this fan, Junxiong Textile Factory installed 10 fans in two workshops of the same area. One workshop uses ordinary air coolers, and the other uses PanGood’s axial flow air coolers. Each fan is equipped with an independent electric meter for power consumption monitoring. "The electric meters are of the same model, brand, and batch to avoid errors as much as possible," said Mr. Huo.

Since this batch of disc hub axial flow fans was installed and put into use at the end of June 2022, "except for a few days off during national statutory holidays such as the Spring Festival, Dragon Boat Festival, and Tomb Sweeping Festival, this batch of fans have basically been in operation 7×24 hours a day without stopping," said Mr. Huo. Electric meter statistics show that the electricity consumption of an ordinary air cooler reached 7190.1 kWh this year, while the axial flow fan with PanGood’s axial flux motor consumed only 2373.1 kWh of electricity in the same period, a difference of more than three times. According to the average unit price of 0.78 yuan/kWh for electricity consumption in the textile industry in Zengcheng District, Guangzhou, a PanGood’s axial flow fan can save about 3,800 yuan in electricity costs a year. Junxiong Textile Factory uses 10 PanGood’s axial flow fans, saving about 38,000 yuan in electricity costs a year.

From June 2022 to the end of June 2023, the power consumption of PanGood’s axial flow fan was 2373.1 kWh

From June 2022 to the end of June 2023, the power consumption of ordinary air coolers is 7190.1 kWh

On the other hand, "after using ordinary air coolers for a period of time, belt aging and other problems are likely to occur, further increasing the cost of use and maintenance; PanGood’s axial flow fan adopts a motor direct drive method, without a transmission belt, with better efficiency and no maintenance required," said Tian, the factory manager of Junxiong Textile Factory. When the seasons change, PanGood’s axial flow fan can also adjust the speed to maintain a constant temperature. "In winter, it is enough to adjust it to 700 rpm, and in summer, it is turned to 1100 rpm to ensure that the workshop temperature will not exceed 25℃." Ordinary air coolers do not have this function, which objectively increases the expenditure of ineffective power consumption. “Under the background of "dual carbon", China's textile industry continues to accelerate towards the direction of green, low-carbon and high-quality development. Under the new policy and market environment, how to achieve energy conservation and carbon reduction, cost reduction and efficiency improvement is one of the core topics of communication among peers” , Mr. Huo said, “the reason why Chinese-made textiles can be marketed all over the world is largely due to the close communication and mutual learning within the industry. Now, in the communication and interaction between peers and the sharing of new technologies and new products, I will focus on recommending PanGood's axial flow fan to everyone. Many friends also come to the factory to learn about the application effect. Everyone praises this new fan and says that they will apply it in their own workshop as soon as possible." In the future, PanGood will continue to delve deeply into user needs, continuously strengthen original and leading scientific and technological innovation and implementation of results, provide more high-quality technology and product support for China's intelligent manufacturing, and create a larger market and business space.